Starbucks Supply Chain Assessment + Product Redesign

OUTCOMES:

Cost & Material Savings

50% Lower Material Costs

30% Reduction in Shipping Materials

Overall $10M Reduction in Costs

Improved Material Choices

Swapped product line to Post-Consumer Recycled Plastics & Recycled Film

Reduced Waste in Supply Chain

Long Term Benefits

Switched to Green Energy Manufacturing

Built Regulatory Resiliency

Recipe Change Supports Long Term Crop Sustainability

Opportunity

In the context of a coffee partnership negotiation, Starbucks embarked on a holistic transformation of one of their consumer packaged goods (CPG) products. Their goal was to enhance supply chain circularity, reduce costs, and ensure long-term sustainability.

Approach

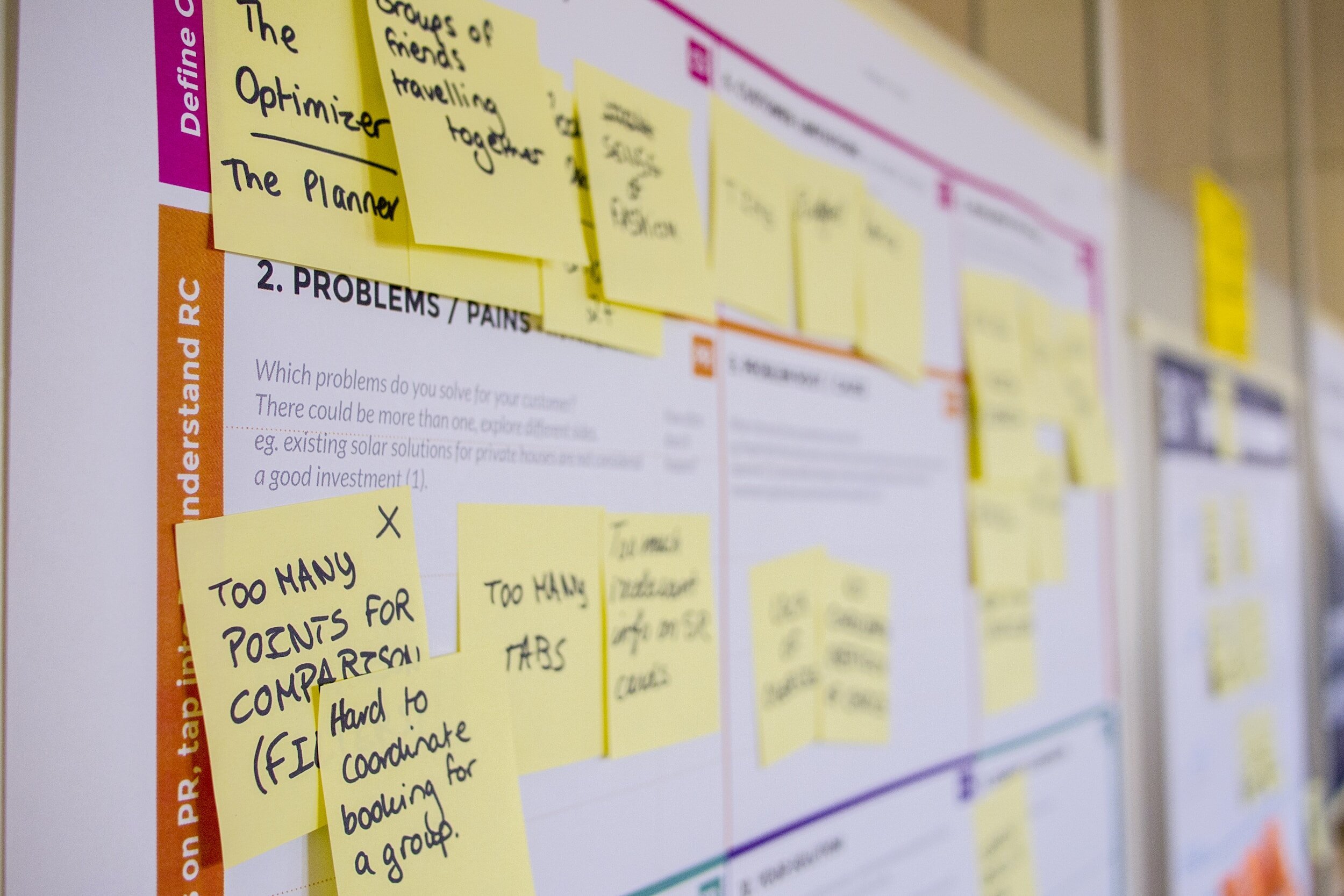

We began with a Lifecycle and System Analysis, identifying opportunities for improvement across the product’s supply chain: from sourcing raw materials to optimizing design, packaging and logistics.

Collaborative design-thinking and research sessions engaged stakeholders from various domains within both Starbucks and Nestle teams.

Outcomes

The outcome was a range of product offerings designed to reduce manufacturing waste, minimize plastic content, and prioritize post-consumer recycled materials, including a $10M reduction in cost, and a secured partnership with Nestle.